30. Fakuma | 12 to 16 October 2026 | Messe Friedrichshafen

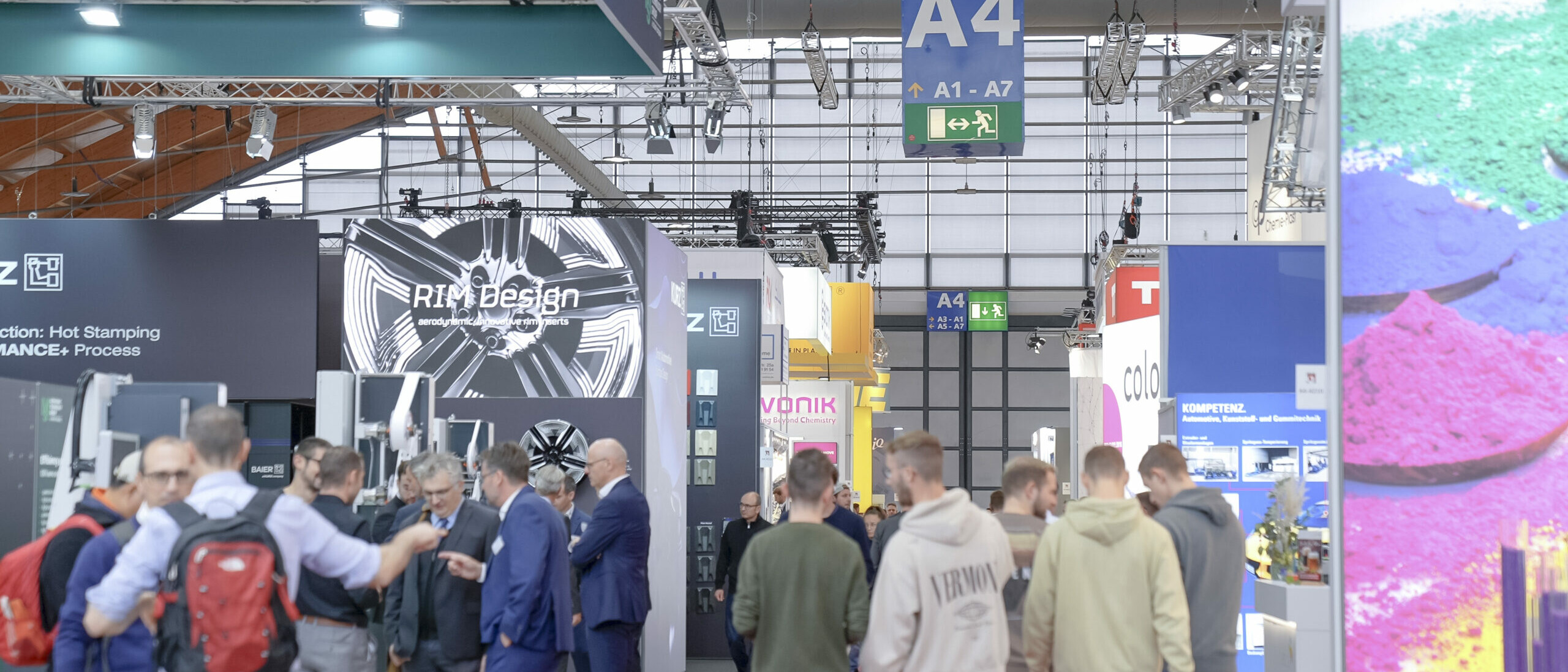

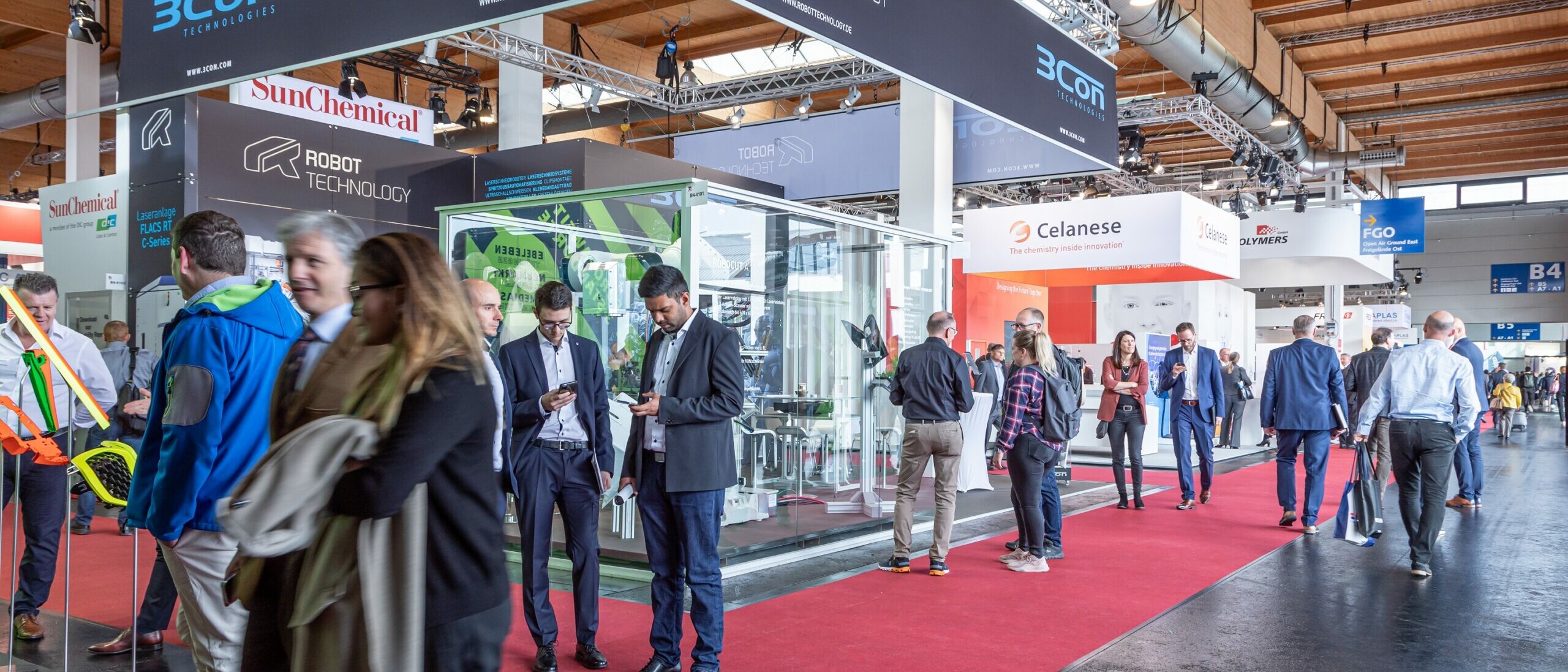

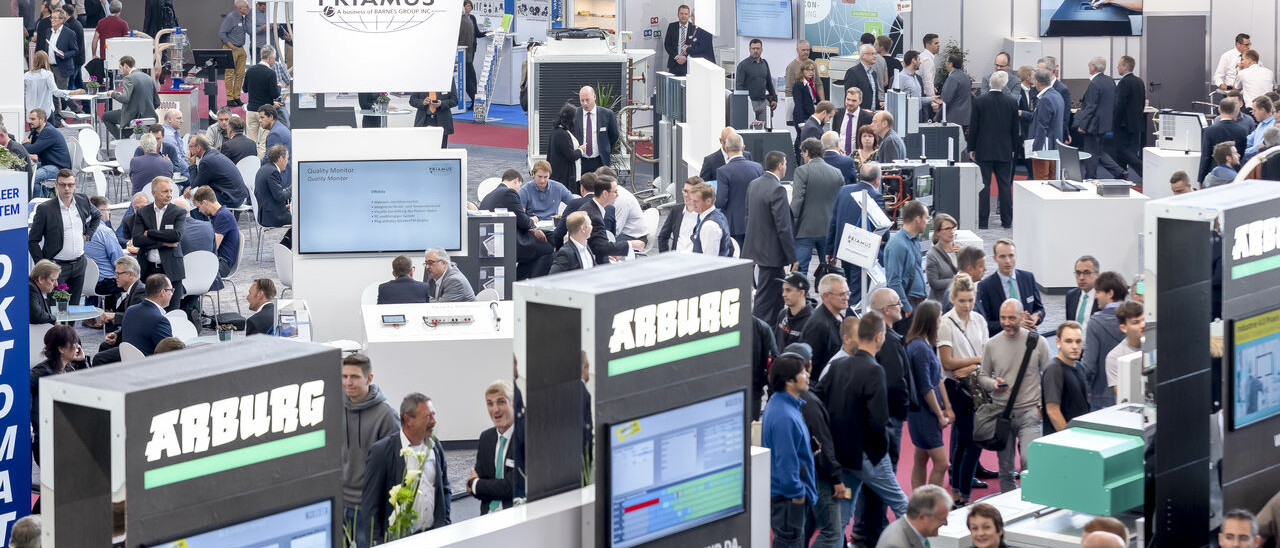

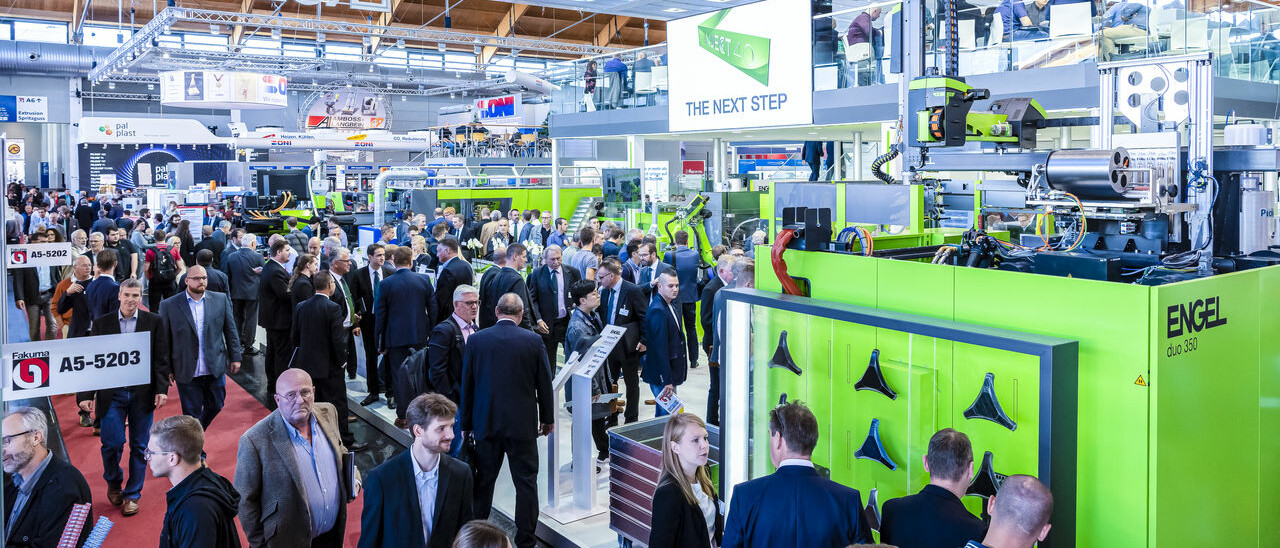

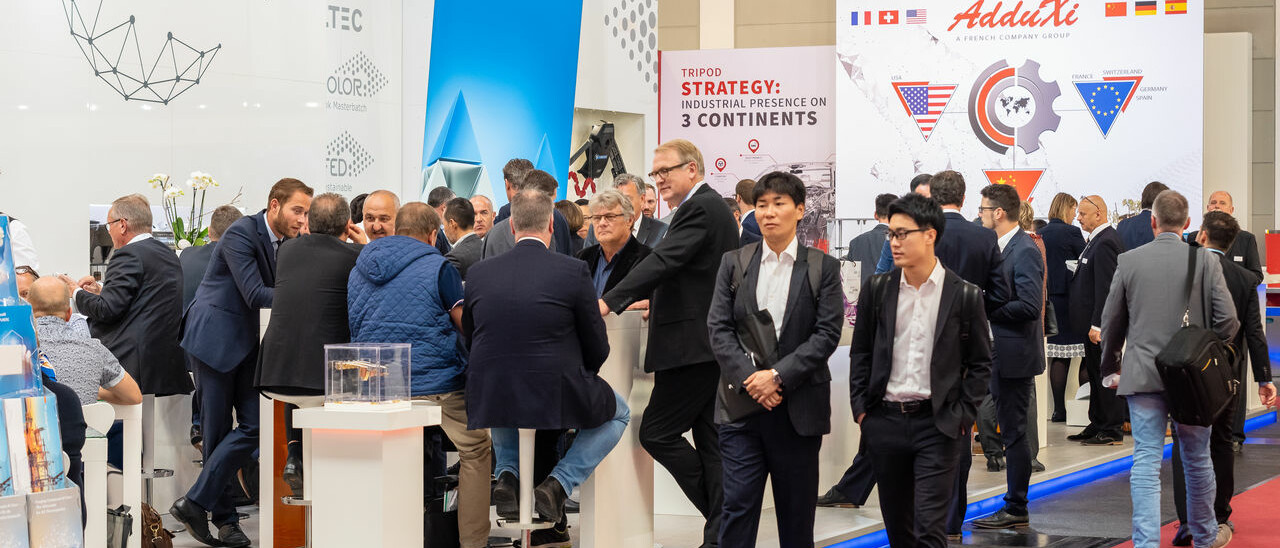

At the world's leading trade event for industrial plastics processing, 1,639 exhibitors presented their international range of products and services. Fakuma offers a comprehensive overview of all plastics technologies.

Trade fair for plastics processing

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

Current topics on plastics processing

5. May 2025

Great Interest for 30th Fakuma in Fall 2026

Fakuma 2026 will be an anniversary event, and it’s already arousing great interest a year and a half in advance: two thirds of all available booth…

2. December 2024

Fakuma 2026 with New Scheduling

The 30th Fakuma international trade fair for plastics processing will take place in just less than two years with new event scheduling: Fakuma’s…

25. October 2024

Tremendous Success for Career Friday!

Career Friday, held as part of the 29th Fakuma international trade fair for plastics processing, was a complete success in terms of promoting young…

21. October 2024

Fakuma 2024 Once Again a Family Celebration for the Plastics Industry

The 29th Fakuma international trade fair for plastics processing closed in Friedrichshafen as a great success. 1639 exhibitors presented their…

19. October 2024

Fakuma 2024 – Trade fair films “Statements & Scenes”

Fresh ideas and practical solutions are generated through direct dialogue and exchange at eye level. These open up innovative approaches and show…

16. October 2024

Fakuma 2024 got off to an excellent start

The 29th Fakuma, the international trade fair for plastics processing, has kicked off in Friedrichshafen with 1,639 exhibitors in twelve almost full…

30. September 2024

Fakuma 2024 is On the Home Stretch!

The 29th Fakuma international trade fair for plastics processing has entered the home stretch and will open its doors in about two weeks. The…

21. August 2024

Flying high and more: fascinating highlights at Fakuma 2024!

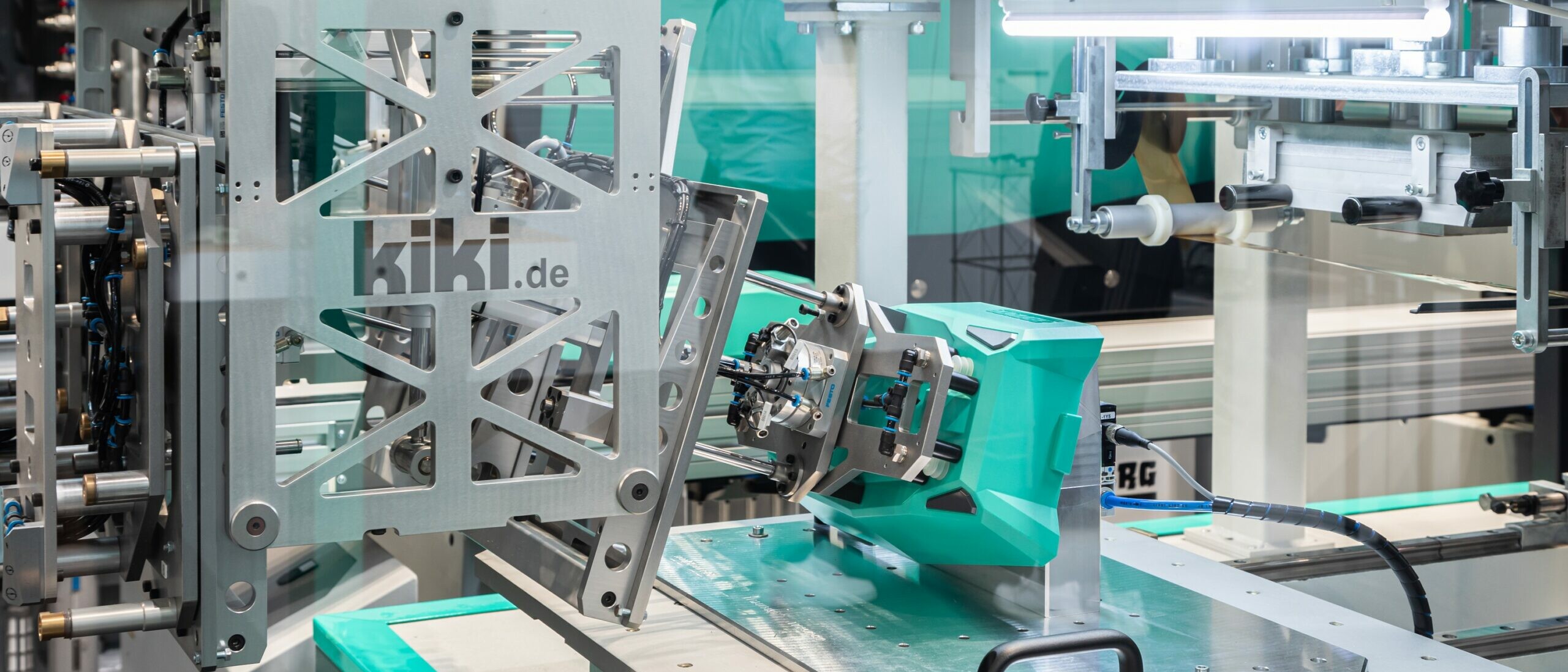

This year's Fakuma, the international trade fair for plastics processing, will be reaching new heights in the literal sense of the word from 15 to 19…

2. July 2024

Materials, Processes, Energy: the Focus is on Efficiency at Fakuma 2024

The industry will meet in Friedrichshafen for the 29th Fakuma international trade fair for plastics processing from the 15th through the 19th of…

3. June 2024

The 29th Fakuma presents “Mold your dreams, mold your future” – Career Friday for pupils, students and career starters

The organizer Schall Messen and the advisory boards of the Fakuma trade fair, one of the most internationally renowned events for plastics processing…

19. February 2024

“Questions? Get the Answers at Fakuma 2024!”

Exhibitors and expert visitors will meet at the 29th Fakuma international trade fair for plastics processing from the 15th through the 19th of…

6. February 2024

Fakuma 2024: Focus on Efficiency

Efficiency in terms of materials, energy and operation – this is currently one of the plastics industry’s top priorities and will be the focus of…

29. January 2024

Industry Characterized by Change

For COLLIN Lab & Pilot Solutions, Fakuma is one of the most important trade fairs in Europe, as confirmed by managing director Dr. Friedrich Kastner.…

23. October 2023

Fakuma 2023 – Innovation Fireworks!

The 28th Fakuma international trade fair for plastics processing was held successfully from the 17th through the 21st of October, 2023. With 1636…

21. October 2023

Many thanks to all exhibitors, media partners and trade visitors for the successful 28th Fakuma!

Fakuma 2023 showcased the latest, most efficient and currently most sustainable cutting-edge technologies in the plastics processing industry - live:…

21. October 2023

Best of Fakuma 2023 | Best of “Digital meets Circular Economy

Fakuma 2023: The 28th international trade fair for plastics processing showcased innovations in efficiency, digitization, and the circular economy.…

21. October 2023

New Life for Plastic Waste | Tide Ocean – Marc Krebs

Tide Ocean combats plastic waste in critical regions. Through local communities, high-quality recycled materials emerge with social impact.

20. October 2023

Fakuma 2023 – automated technologies, intelligent solutions, creative impulses

Digitalisation and automation support the efficient use of all resources in the production, processing, application and reuse or recycling of…

20. October 2023

Plexiglas® Innovations | Röhm – Siamak Djafarian

Siamak Djafarian, Vice President of Molding Compounds, introduces the latest innovations from Röhm and Plexiglas® at Fakuma 2023.

20. October 2023

Engineering Polymers | Nurel – Leyre Quibus

Nurel, a Spanish tech company, is revolutionizing the polymer industry with innovation and sustainability.

20. October 2023

Energy Efficiency for Plastic Processors | ONI – Rüdiger Dzuban

Rüdiger Dzuban from ONI presents energy-efficient systems for plastic manufacturers at Fakuma 2023. With innovations in cooling technology and heat…

20. October 2023

Flame Retardants and Stabilization Packages | Green Chemicals – Micaela Lorenzi

Micaela Lorenzi, CEO of Green Chemicals provides innovative and eco-friendly solutions for polymers and their recycling at Fakuma 2023.

20. October 2023

Round Table at Fakuma 2023: Plastic – Resource Instead of Problem Material!

Experts at Fakuma 2023 emphasize: Plastic is essential for environmental protection & CO2 saving. Joint action is the key to a circular economy.

19. October 2023

At Fakuma 2023: Where business is generated in the plastics industry

The efficiency of the plastics industry is demonstrated at Fakuma 2023 in excellent moulding and colouring manufacturing processes, which are…

19. October 2023

Innovative Thin-Film Processes | Leonhard Kurz – Jörg Stierand

Jörg Stierand from Leonhard Kurz introduces innovative thin-film processes for cars at Fakuma2023. This technology protects, decorates, and is…

19. October 2023

Sustainability and Recycling of Technical Plastics and Additives | Marubeni – Tim Steltenkamp

Tim Steltenkamp from Marubeni showcases sustainable recycling solutions for technical plastics at Fakuma2023.

19. October 2023

Innovative Technical Plastics | Aurora Kunststoffe – Thomas Rätzsch

Thomas Rätzsch von Aurora Kunststoffe stellt auf der Fakuma 2023 nachhaltige technische Kunststoffe für die Autoindustrie vor. Eine Kombination aus…

19. October 2023

PCR Recyclates, Bioplastics, and Screw Cleaners | WIS Kunststoffe – Daniel Römhild

Daniel Römhild from WIS Kunststoffe introduces sustainable innovations at Fakuma 2023, including PCR recyclates, bio-plastics, and a revolutionary…

19. October 2023

Cooling and Temperature Control Solutions for the Plastic Industry | technotrans – Nico Küls

Nico Küls introduces innovative cooling and temperature control solutions for the plastic industry at Fakuma2023 with technotrans.

19. October 2023

Colors for Plastics | Deifel Buntfarbenfabrik – Bernd Schäfer

Since 1921, Deifel has been a pioneer in colors. Discover our innovations for e-mobility and sustainable biopolymer solutions.

18. October 2023

Fakuma 2023 – Experience the future of plastics processing live.

At Fakuma, the international trade public will experience the latest, most efficient and currently most sustainable cutting-edge technologies of the…

18. October 2023

Innovations in Clamping Technology | Jens Götze – AMF

Innovations in clamping technology by AMF. Jens Götze emphasizes: "A running machine earns money, a halted one costs." Discover more at Fakuma2023.……

18. October 2023

Injection Molding Machines and Additive Manufacturing | Christoph Schumacher – ARBURG

Dr. Christoph Schumacher from ARBURG showcases innovations at Fakuma 2023 and celebrates 100 years of plastic innovation.

18. October 2023

Smart and Efficient Plastic Recycling Systems | Robin Roth – Erema

As a pioneer in the recycling industry, Erema will present innovative technologies for efficient plastics recycling at Fakuma 2023.

18. October 2023

Innovation Drivers in Plastic Processing at Fakuma 2023

The innovation drivers Ingemar Bühler, Michael Weigelt and Marc Krebs present innovations and challenges in plastics processing and technology at…

17. October 2023

Fakuma 2023 – energy-efficient applications, resource-saving processes and future-oriented business models

Digitalisation and circular economy, cutting-edge technologies and forward-looking innovations, intelligent and practice-oriented solutions: Fakuma…

26. September 2023

Austrian Plastics and Plastics Processing: Surprisingly Ingenious

The Austrian plastics and plastics processing industry is a powerhouse that encompasses the entire value chain, from raw materials to the finished…

13. September 2023

Fakuma 2023: Plastics Festival in Friedrichshafen

Fakuma 2023 will surely be a feast for plastics. “Spirits are high, the exhibitors are excited about presenting their future-oriented solutions and…

7. September 2023

Plastics Headed for the Future

"For us, the Fakuma trade fair is a good opportunity for meeting our customers and engaging in dialogue with international expert visitors, as well…

14. June 2023

Fakuma 2023: Focus on Plastic as a Recyclable Material!

With excitement and anticipation, the industry is looking forward to the 28th Fakuma international trade fair for plastics processing in…

26. April 2023

Plastics for the Future

Remaining booth locations are filling up in the exhibition halls in Friedrichshafen for the 28th Fakuma international trade fair for plastics…

24. April 2023

Practical Relevance and Continuity are Fakuma’s Success Factors

Ever since its premiere in 1981, Fakuma has had a firm foothold in the trade fair calendar of technotrans solutions GmbH (formerly gwk). As one of…

24. March 2023

Fakuma 2023 – Highly Dynamic and Packed with Innovative Power

The 28th Fakuma international trade fair for plastics processing is being eagerly awaited with great anticipation. The world’s leading trade fair for…

27. February 2023

“Fakuma is the Most Important Trade Fair for Our Company”

“Only those products which are optimally designed, engineered and produced – in terms of recyclability – will be good products in the future.” The…

21. February 2023

Fakuma with high international attention

"For us, Fakuma is one of the foremost trade fairs anywhere in the world and we always look forward to it with great anticipation. We engage in very…

16. February 2023

Full Exhibition Halls and Great Enthusiasm for Fakuma 2023

It’s filling up at the Friedrichshafen Exhibition Centre: The 28th Fakuma international trade fair for plastics processing will take place from the…

1. December 2022

60 years of Schall – 28th Fakuma – with exhibitor ARBURG

In Schall's anniversary year, we visit partners of excellence at our international trade fairs. Today our path leads us through the picturesque Black…

7. April 2022

28th Fakuma in October 2023 – Booking Levels Already High

The next Fakuma international trade fair for plastics processing will take place in Friedrichshafen on Lake Constance from the 17th through the 21st…

19. October 2021

Fakuma 2021: Inspiring Plastics Live!

The 27th Fakuma international trade fair for plastics processing celebrated an inspiring restart in Friedrichshafen from the 12th through the 16th of…

16. October 2021

Fakuma 2021 – Statements, Highlights & Scenes – Thank you and see you again in 2023!

Our sincere thanks go out to all exhibitors and expert visitors for a successful 27th Fakuma at the Friedrichshafen Exhibition Centre! We published…

15. October 2021

FAKUMA latest news – the exhibition-news from plas.TV

FAKUMA 2021 I Messe Talk I Prof. Dr. Hans-Josef Endres Only the look of an expert allows a realistic assessment and an answer to the question of how…

29. September 2021

Exclusively for the 27th Fakuma – U.S. Plastics Market Update

This report provides an update of the U.S. plastics market since the coronavirus pandemic that resulted in the COVID-19 recession in the U.S. This…

14. September 2021

Fakuma 2021 ready for the starting gun

Only a few more weeks until the first major international presence event for the entire plastics industry in Germany: the 27th Fakuma - International…

6. August 2021

Circular Economy at the Fakuma 2021 industry highlight

The 27th Fakuma - International Trade Fair for Plastics Processing - invites you to Friedrichshafen, Germany, from October 12 to 16, 2021, for the…

3. August 2021

The personal contact is not replaceable

Personal contact with customers, partners and interested parties at trade shows cannot be replaced by digital formats. This clear statement by Sandra…

16. July 2021

Digitization in mechanical engineering – an evolutionary process!

Current topics in the plastics processing industry include increasing energy efficiency in production, the circular economy, and the development and…

1. June 2021

Fakuma 2021 will be exciting – and characterized by change

Exhibitors and trade visitors are eagerly awaiting the 27th Fakuma - International Trade Fair for Plastics Processing - from October 12 to 16, 2021,…

11. March 2021

Fakuma 2021: Topics of the future

For the plastics processing industry, in addition to the digital transformation, the change from a linear to a circular economy is also on the…

10. February 2021

Plastics are indispensable!

With Julia Große-Wilde, the Gesamtverband Kunststoffverarbeitende Industrie (GKV) in Berlin has a new managing director since the beginning of the…

9. December 2020

Switching to a circular economy

he next Fakuma - International Trade Fair for Plastics Processing - will take place from October 12 to 16, 2021. The 27th trade fair, internationally…

1. December 2020

“The transformation of the plastics industry toward greater sustainability has begun”

The Corona crisis has shaken up the markets - including that of plastics recycling. Until about three years ago, the cost of recycling was almost…

5. November 2020

Fakuma 2021: Industry and technology barometer in preparation

The 27th Fakuma - International Trade Fair for Plastics Processing - from October 12 to 16, 2021 is in intensive preparation. The trade show, which…

5. October 2020

Interview with HNP Microsystems

We have developed a new system for metering liquid colors in plastic injection molding. For this purpose, we have integrated our pump technology,…

25. September 2020

Fakuma-Virtuell: Online meeting place for the plastics industry

The digital trade fair marketplace Fakuma-Virtuell is all about plastics processing and machining. Here, exhibitors at the 27th Fakuma -…

3. August 2020

Official start of Fakuma-Virtuell! The new marketplace for implementing digital transformation in the plastics industry

Fakuma, the international trade fair for plastics processing, has officially launched its new digital trade fair platform Fakuma-Virtuell.…

23. July 2020

Special press release: Next Fakuma in October 2021!

Together with the Fakuma 2020 exhibitor advisory board, the Schall trade fair company has decided to postpone the 27th Fakuma - International Trade…

29. June 2020

Special press release: Fakuma 2020 gets ready for takeoff!

The 27th Fakuma - International Trade Fair for Plastics Processing - is gearing up for its next trade show appearance from Oct. 13 to 17, 2020.…

21. April 2020

Fakuma 2020: Implementing the digital transformation

From Oct. 13-17, 2020, trade visitors will get an overview of all modern plastics technologies when some 2,000 exhibitors present themselves in…

20. February 2020

Fakuma 2020: Digitalization and the circular economy

Around 2,000 exhibitors are expected to attend the 27th Fakuma - International Trade Fair for Plastics Processing - from Oct. 13-17, 2020, in…

4. July 2019

Fakuma 2020: Digitization, networking and sustainability

Further development at a gallop: all the big names in plastics processing will meet at the 27th Fakuma - International Trade Fair for Plastics…

19. March 2019

On trend: digital transformation and circular economy

Fakuma - International Trade Fair for Plastics Processing, recognized as an industry and technology barometer - demonstrates in fast motion how…

19. March 2019

On trend: digital transformation and circular economy

Fakuma - International Trade Fair for Plastics Processing, recognized as an industry and technology barometer - demonstrates in fast motion how…

21. November 2018

In trend: digital transformation and resource-saving future technologies

Fakuma - International Trade Fair for Plastics Processing, for years the industry and technology barometer of the plastics industry - demonstrates in…

22. October 2018

Plastics processing in digitization mode

In the border triangle at Lake Constance, everything that is important in the world of plastics gathered for the 26th time at Fakuma - the…

22. August 2018

Plastics processing: injection molding and more

Highly stressable, continuous fiber-reinforced and functional plastic components offer great lightweight construction potential for the automotive…

12. July 2018

Demand for plastics and plastics processing increases

Plastics are booming. However, not only the demand is increasing, but also the demands on material and processing quality. Modern solutions for…

24. May 2018

Plastics can also be “green”!

Ecologically responsible handling of plastics includes the entire processing chain. What happens to PE, PS, ABS or PET and CFRP today when it has…

4. April 2018

Foam and composite plastics save weight!

Fakuma - International Trade Fair for Plastics Processing presents a comprehensive overview of all plastics technologies in Friedrichshafen. Also in…

8. February 2018

Plastics industry: demand unbroken

From sports cars to consumer goods, from eyeglass lenses to packaging materials to yoga mats. More and more products today are made of the high-tech…

Consultation and contact

Trade fair project manager

Annemarie Schur

P. E. Schall GmbH & Co. KG

Gustav-Werner-Strasse 6

72636 Frickenhausen

Germany

+49 (0)7025 9206-650

+49 (0)7025 9206-88650

schur@schall-messen.de

Foreign representatives

Belgium, Luxembourg, Netherlands

InterMundio BV

Sigrid Jahn

Netherlands

China, Hongkong

Dragon Invest Co., Ltd. Shanghai

Hermann Bohle

P. R. China

+86 21 62 15 56 68

hermann.bohle@dragon-invest.com

www.dragon-invest.com

Italy

Emtrad

Edgar Mäder

Italy

Südkorea, Taiwan

THETW Co, Ltd.

Ben Huang

Taiwan

Türkiye

RFL FAIR

Mehmet Ali Dincer

Türkiye

Foreign representatives

Annemarie Schur

P. E. Schall GmbH & Co. KG

Gustav-Werner-Strasse 6

72636 Frickenhausen

Germany

+49 (0)7025 9206-650

+49 (0)7025 9206-88650

schur@schall-messen.de

InterMundio BV

Sigrid Jahn

Netherlands

Dragon Invest Co., Ltd. Shanghai

Hermann Bohle

P. R. China

+86 21 62 15 56 68

hermann.bohle@dragon-invest.com

www.dragon-invest.com

Emtrad

Edgar Mäder

Italy

THETW Co, Ltd.

Ben Huang

Taiwan

RFL FAIR

Mehmet Ali Dincer

Türkiye